Eco Value Chain

Hankook Tire & Technology remains fully committed to bringing forth an environment-friendly circulation structure. We continue to make investments and efforts to reduce environmental impacts during product and manufacturing processes as well as the entire process that each product is involved in.

Reduction of GHG emissions

We will establish a specific carbon reduction plan and meticulously implement it in stages to achieve our reduction goals, based on four major initiatives: establishing a low-carbon management system, improving the process energy use efficiency, expanding the use of renewable energy, and introducing renewable energy innovative reduction technologies. In the short term, the aim is to minimize energy use across the tire manufacturing process while laying the groundwork for a long-term energy transition on a continuous review basis in order to discover eco-friendly alternative energy. We will establish a carbon-neutral roadmap suitable for the 2050 value chain which will allow us to develop and implement a number of detailed implementation strategies focused on each area.

Scope 1 & 2 greenhouse gas emissions

(Unit: tCO2-eq)

- 2019

-

-

1,253,724

-

- 2020

-

-

1,165,281

-

- 2021

-

-

1,130,801

-

- 2022

-

-

1,152,865

-

- 2023

-

-

1,101,599

-

- Scope 1, 2, change in emission calculation scope (including 8 factories, 3 major offices, and 4 major subsidiaries)

- Scope 1&2 greenhouse gas emissions reduced by 12% in 2023 compared to 2019

- Greenhouse gas intensity (tCO2/product ton) reduced by 5% in 2023 compared to 2019

GHG Reduction Target

Received Korean mobility industry’s first SBTi approval for its greenhouse gas reduction target

The Science-Based Targets initiative(SBTi) is a collaboration between several international organizations, including the United Nations Global Compact(UNGC), the World Resources Institute (WRI), the World Wide Fund for Nature (WWF), and the Carbon Disclosure Project (CDP), among others. The main goal of the SBTi is to help companies and organizations set ambitious and effective greenhouse gas emission reduction targets that are aligned with Paris Agreement 1.5℃ Target. Hankook Tire has received approval from SBTi for its near-term 2030 greenhouse gas (GHG) reduction goals and net-zero target by 2050, helping the company gain momentum in the realization of its ‘2050 Carbon Neutrality Roadmap.’

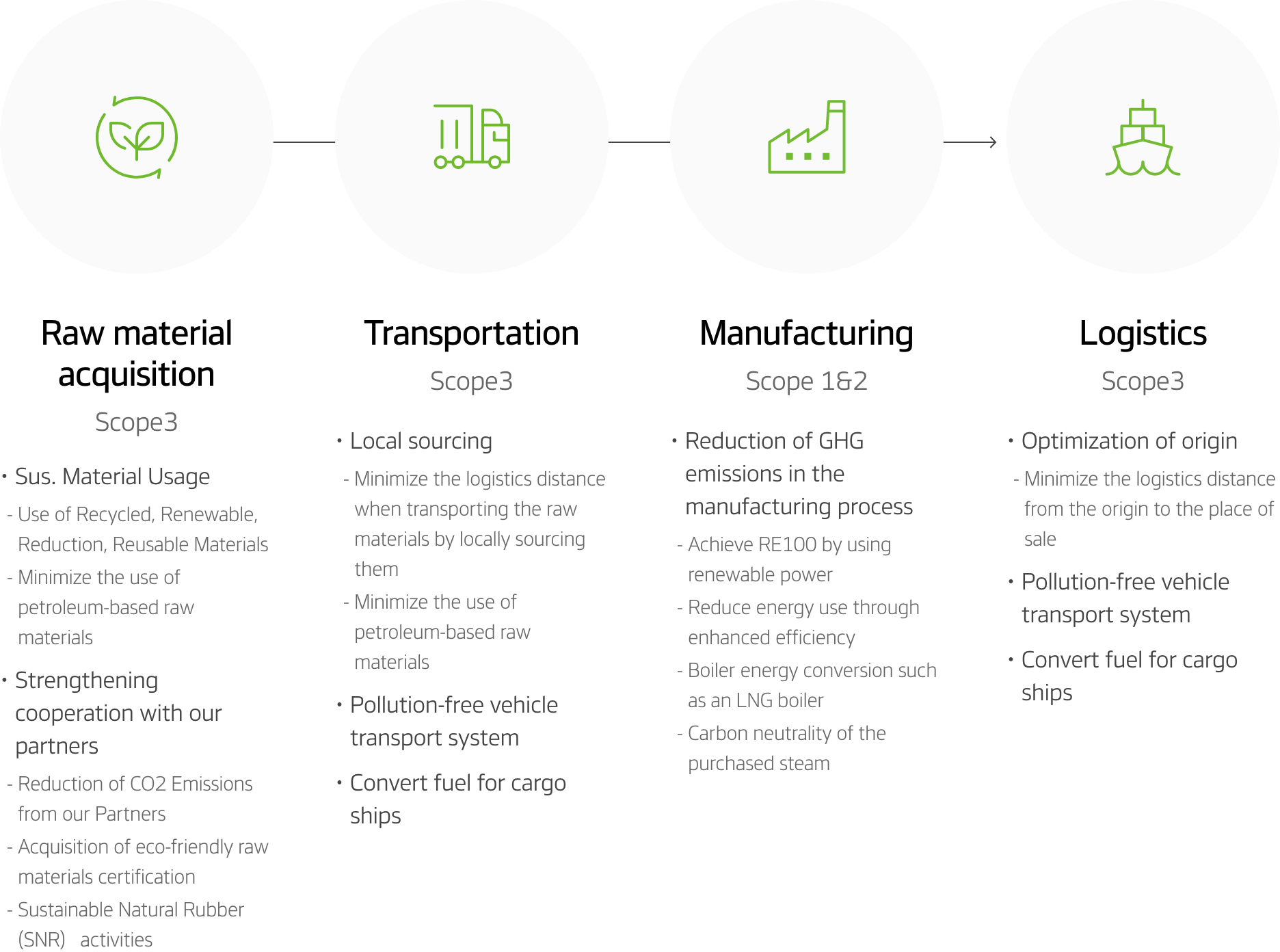

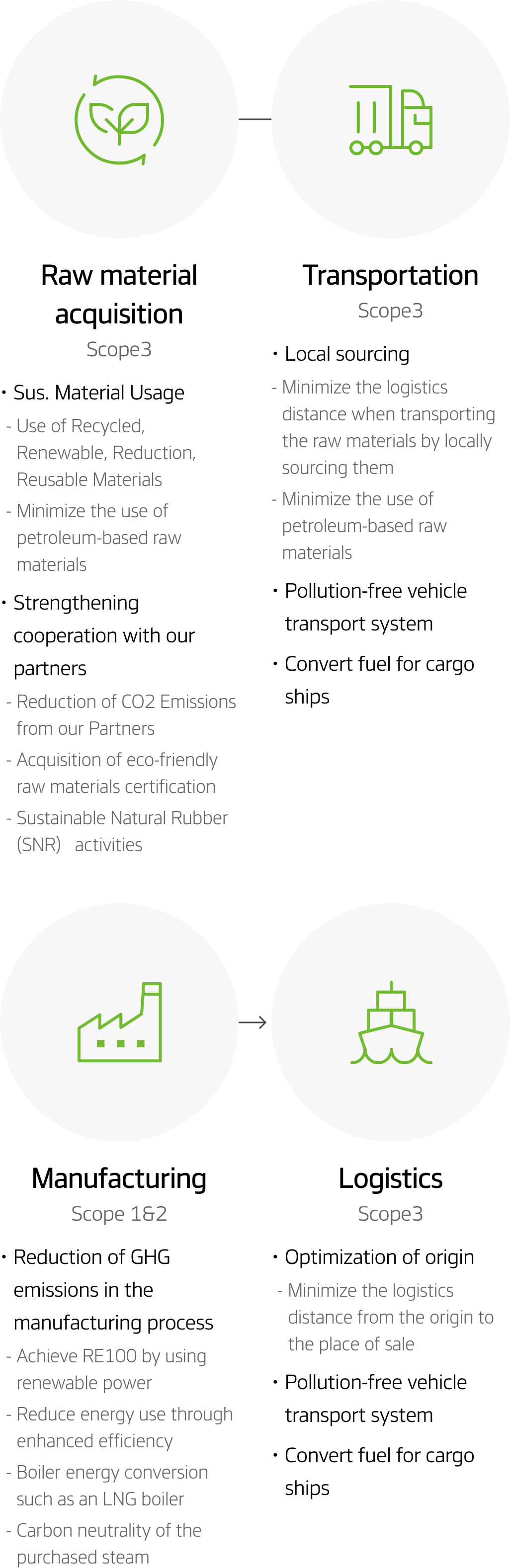

Carbon Neutrality Execution Strategy per Stages

Achieving carbon neutrality through greenhouse gas (GHG) reduction activities throughout the value chain (raw material acquisition, transportation, manufacturing, and logistics)

Production with minimal environmental impact

We carry out a wide variety of activities to reduce the environmental impact of our production activities.

Waste treatment performance

(Unit: ton)

- 2018

-

-

56,041

-

- 2019

-

-

55,233

-

- 2020

-

-

49,077

-

- 2021

-

-

49,603

-

- 2022

-

-

48,650

-

- 2023

-

-

49,394

-

- Water intake intensity: 0.6% decrease compared to the previous year

- Treatment water recycling rate: Domestic factory average 73.1%

2023 CDP Report Download

2022 CDP Report Download